Application areas

- Automotive industry and suppliers

- Aviation industry

- Consumer goods

- Toy industry

- Art and art history

- Mold making (rapid tooling)

- Medical technology

- Architecture and landscape design

- Various other applications

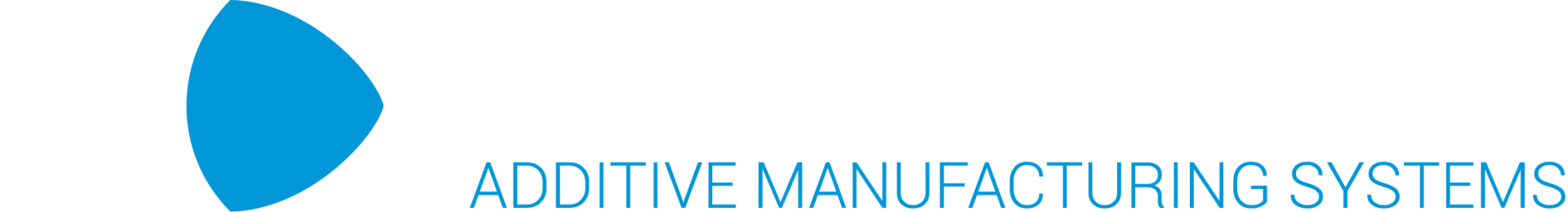

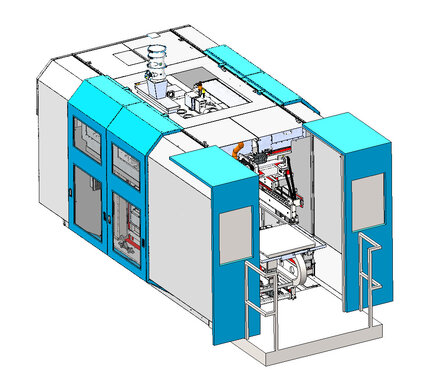

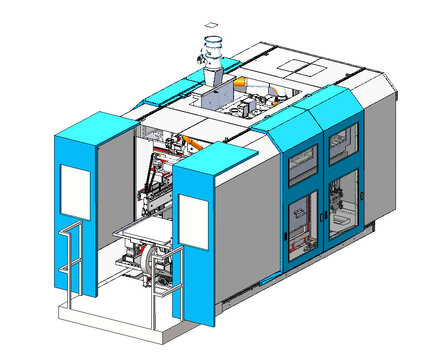

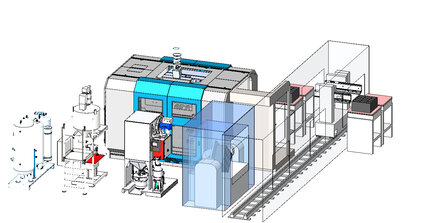

3DM-AM printing systems

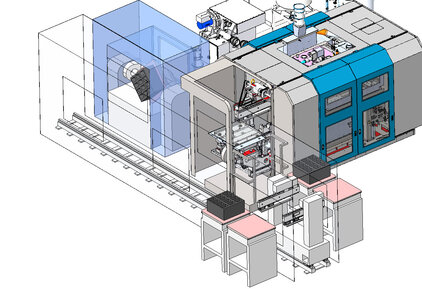

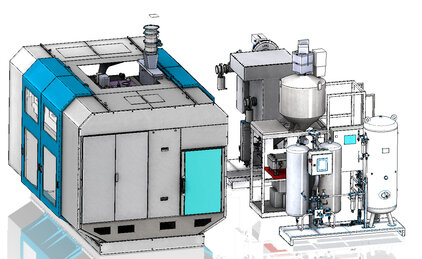

The 3DM-AMS additive manufacturing system developed in-house is a three-component system that can process plastics, metals and ceramics at the same time. The customizable 3DM AMS series is flexible in terms of customer requirements regarding installation space size, wavelength, postal processes, etc.

This innovative 3D printing system combines all manufacturing processes in a fully automatic process flow.

System 3DM-AMS 800

Technical data

- Construction volume: 800 x 800 x 500 mm

- Speed: > 60 mm/h (depending on the material)

- Layer thickness: 0.01 mm to 0.12 mm

- Laser: Fiber laser 450 - 1070 nm (optionally selectable)

- Compressor: Min. 5l/h, 7,500 hPa

- Optics: VarioScan up to 30 m/s

- Dimensions: 12,000 x 2,500 x 2,500 mm

- Electric: CEE 32A

- Weight: 12,000kg

- Consumption: Rated power 20kW, typical 15kW

- Data preparation: 3DM AMPC

- Atmosphere: Nitrogen/Argon

- CAD interface: STL (depending on material)

- Operating system: WIN 10 Pro

- Network: Ethernet

- Certification: CE/UL

Plate tower, powder conveying, stripping and screening station, stress relief annealing, part post-treatment and reproducible surface blasting treatment optionally integrated.

Can be used for plastics, metals and ceramics.

All from a single source

In over 30 years of working in the field of additive manufacturing, we have developed into a specialist for AM printing systems. We see ourselves as a partner in all questions regarding AM printing technology. Our portfolio includes:

- Additive Manufacturing 3D machine systems // 3DM-AMS

- Neutral, manufacturer-independent advice and sales of AM printing systems (LM/LS)

- Procurement of used AM laser sintering machines

- Maintenance & Repair

- Custom conversions

- Complete overhauls and upgrades of existing printing systems

- Materialize Control Platform

- Material development // Material testing for LM and LS systems

- Training & Support

Do you have questions? We are always there for you!

In order to offer you the perfect solution, we need precise information about your requirements.

Let us know what you are looking for and you will receive the best possible support.